Working in confined spaces – Did you cover your risks

Most industrial facilities have confined spaces. They often get overlooked because access to them is rare.

Most industrial facilities have confined spaces. They often get overlooked because access to them is rare. Not surprisingly, many facility managers believe there is no particular reason for concern. The awakening could be a rude one, as several managers have faced criminal prosecution and substantial fines as a result of fatal accidents.

The issue of work in confined spaces is a historical one, yet accidents in these highly dangerous work environments continue to occur. In June 2011 Enhesa carried out a survey on how work in confined spaces is regulated around the globe and how multinational companies should tackle the issue. The survey was triggered by the fact that in the past two years, more than 20 countries reviewed the regulations on the issue.

This article explores the varying approaches to regulating work in confined spaces, focusing particularly on significant differences in definitions and safety requirements. Faced with these varying approaches, it identifies what approach companies should take to cover the risk and ensure compliance worldwide.

Confined Spaces – The hazards

In 1983, a young student engineer was being shown around a dam site where he was to start work on a construction project. As part of the student’s introduction to the site, the employee showing him around took him to a drain area to show him how to measure water in the chamber. The employee opened the manhole cover and entered the chamber. After being at the bottom of the chamber for a couple of seconds he started to climb back up the stairs. Suddenly, he became red in the face and started coughing. He fell down to the water below. The student shouted for help and another worker arrived on the scene. That worker descended into the manhole, started to pull up the other victim, and also collapsed. Another two men descended into the chamber. Both did not come up again. None of the four workers involved survived.

Fatalities in confined spaces happen quickly in seemingly innocuous situations. Inhaling an atmosphere that contains no oxygen causes loss of consciousness in a matter of seconds because such an atmosphere not only fails to provide fresh oxygen but also removes oxygen already present in the bloodstream.

When an oxygen-free atmosphere is breathed, the breathing process is reversed and instead of carbon dioxide, it is oxygen which diffuses from the blood in the lungs to the inhaled air.

There are many industry sectors that carry out work involving confined spaces. The US Occupational Safety and Health Authority (OSHA) estimates that 2 million workers annually enter confined spaces in some 225,000 workplaces. If we translate this statistic globally, it is clear that tens of millions of workers

enter confined spaces every year. The implications are clear – confined spaces are a universal problem for industry. Industries where work involves many confined spaces include oil and gas refineries, electrical and power utilities, nuclear power, food processing, mining, pulp and paper, airlines, waste processing, chemical industry, water and sewer, military, motor, freight transportation, steel manufacture, corrosion removal, tank inspection and repair, shipbuilding and rescue.

The aforementioned example of a confined space accident also highlights the statistic that over half of all workplace confined space fatalities involve workers trying to rescue their colleagues. These fatalities occur where people have gone to the rescue of others and found themselves in similar trouble. Two thirds of all such deaths are caused by dangerous atmospheres, and one third involves toxic gas or oxygen deficiency. Often the danger is not present at the time of entry, which reinforces the need for continuous monitoring and supervision of work in confined spaces. Figure 1 provides an overview of the main causes of accidents and injuries in confined spaces.

The tragic nature of the aforementioned accident is amplified by the fact that through careful management and application of appropriate safety procedures fatalities could have been prevented. Yet to what extent are facilities guided in this aspect by the law? The answer to this greatly depends on which country the

facility is based in.

What is a confined space?

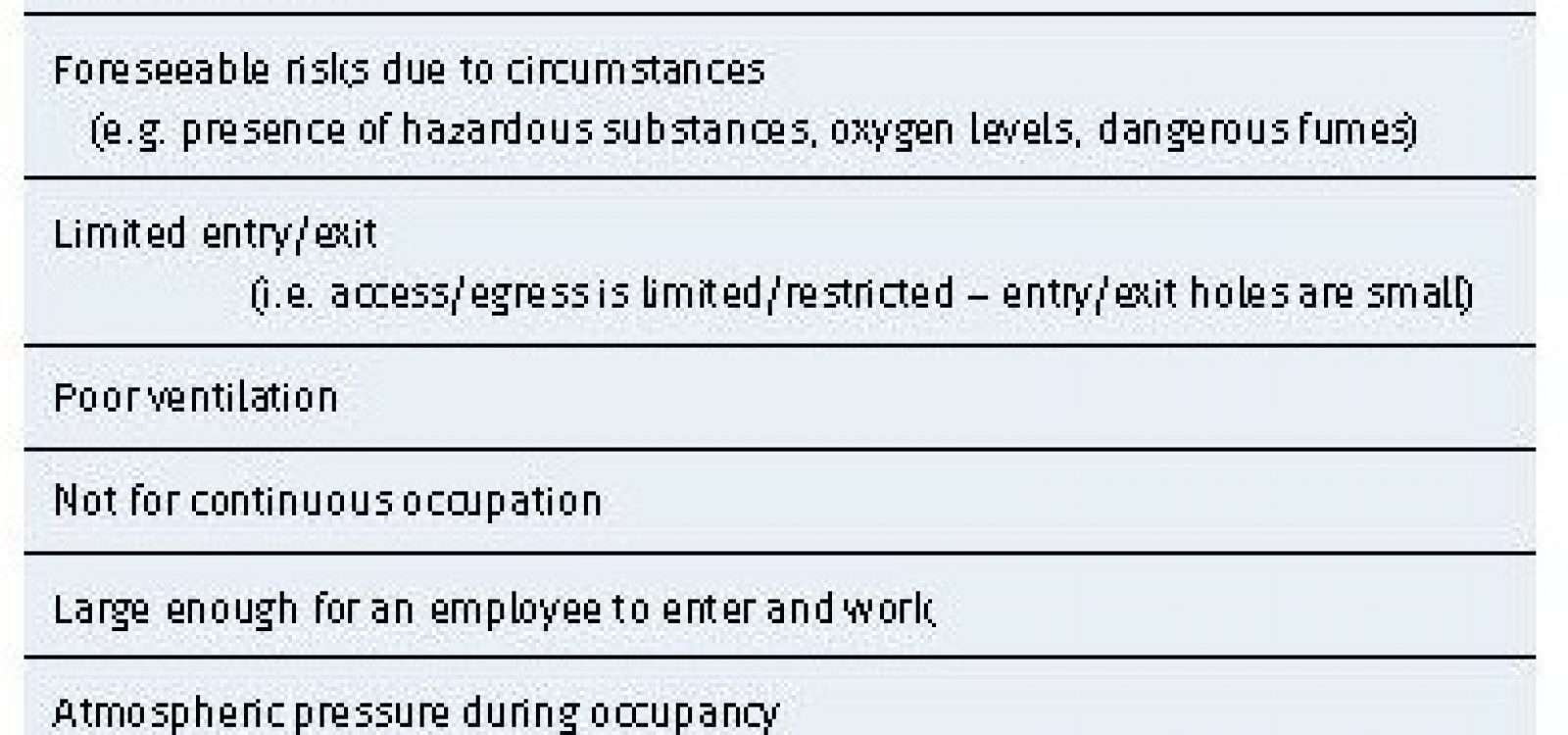

Definitions of confined spaces vary considerably from one country to the next with the result that the impact of any legislation on confined spaces is likely to depend on how they are defined in a particular country. For example, in the United Kingdom, Germany and Ireland, confined spaces are defined broadly and

focus on the notions of an “enclosed” space and the “reasonably foreseeable specified risks” that could be encountered in them.

In contrast, Japan and South Korea have adopted definitions centring on the oxygen-deficient aspect of confined spaces. Roughly translated, confined spaces

are called “oxygen deficiency- danger places” and work carried out in them is referred to as “oxygen depletive operations”. In addition, the Chinese definition specifies that only 1 or 2 persons should be able to enter and that the space is “closed, narrow and poorly ventilated”. There must be limited entry/exit and a depth of 1.2 meters or more.

The US and Malaysia employ several similar elements in their definition of confined spaces including non-continuous occupancy, potential to contain hazardous atmospheres, restricted entry/exit, and large enough for employees to enter and perform assigned work.

The variation in definitions is perhaps surprising when one considers the global incidence and nature of confined spaces. It is even more striking when one

considers that the global potential impact of these different definitions could be considerable. For example, in China, if four people were able to enter a confined space and perform work then they would not be covered by the applicable legislation, whereas workers in a similar situation in say, the UK or Ireland, would be covered.

Similarly, if a worker enters an enclosed space for cleaning purposes in Singapore, and there is a potential for that space to become filled with water, it will not be regulated as the definition only covers the presence or potential presence of hazardous “fumes”.

Of the sixty countries surveyed, not two used the same regulatory approach. Figure 2 summarises recurring elements that appear in one way or another in definitions of confined spaces.

When implementing a corporate confined space entry procedure, it is clear that one cannot rely on the local regulatory definition to achieve a consistent

approach. A corporate definition will need to be developed, preferably with concrete examples to illustrate it.

Four main regulatory approaches

In its global survey of regulatory approaches, Enhesa identified four main regulatory approaches generally taken with regards to confined spaces around the world: the risk-based approach, the command-and-control approach, the approach focused on oxygen deficiency and other countries that regulate it loosely or not at all.

The European risk-based approach

The risk-based approach adopted in Europe focuses on a case-by-case basis and puts the liability with the employer to identify the risk and take the appropriate measures. A similar approach is also adopted in Hong Kong and Australia.

The European Union has not introduced any legislation specifically relating to work in confined spaces (with the exception of temporary or mobile construction sites). However, the Framework Council Directive 89/391/EEC of 12 June 1989 covers all aspects of safety and health at a workplace; as a result the Directive places a duty on employers to take into account the specific characteristics of every workplace (i.e. including confined spaces). Figure 3 summarises the steps to be taken by employers under the risk-based approach.

Specific requirements regarding confined spaces are included in Annex IV to Council Directive 92/57/EEC of 24 June 1992 on safety and health requirements at temporary or mobile construction sites (eighth individual Directive adopted under Directive 89/391/EEC). Annex IV to Directive 92/57/EEC specifies that if need be a confined atmosphere must be monitored and appropriate steps taken to prevent any hazards, a worker may not in any circumstances be exposed to a high-risk confined atmosphere, and a worker must at least be watched at all times from outside and all appropriate precautions must be taken to ensure that he can be assisted effectively and immediately.

Under the risk-based approach the employer has to take the appropriate measures to identify and manage the risks. Although this gives employers the freedom to determine how this is achieved, it also exposes corporate directors and facility managers to criminal liability in case things go wrong. In the UK for example, several company directors or business owners have thus far been found guilty of manslaughter. These convictions were based on the fact that the directors/owners in question had simply ignored or had not given enough regard to health and safety at work. The convictions involved fines and prison sentences. Similar cases were found in Belgium where Directors faced prosecution and were sentenced to prison because of failure to take appropriate safety measures.

Command and control

A second approach is based on command and control and has largely been adopted in North America. Confined spaces are separated into those which are unsafe for entry and require a permit for entry, and those which are less hazardous and therefore do not require such a permit. Standard requirements apply to either category of confined spaces. Singapore has adopted a similar approach.

Under this system, employers must first evaluate the workplace to determine if any spaces are permit-required confined spaces (“permit spaces”). If there are any such spaces, the employer must inform exposed employees (including contractors), by posting danger signs or other means, about the existence and location of and the danger posed by the permit spaces. If employees are required to enter permit spaces, a written permit space program must be developed, which must be available for inspection by employees (including contractors) and their authorised representatives.

Before an employee enters the space, the internal atmosphere must be tested, with a calibrated direct-reading instrument, for oxygen content, for flammable gases and vapours, and for potential toxic air contaminants, in that order. Employees may not enter any permit space with a hazardous atmosphere.

Employers are required to supply all employees and contractors with all equipment, including protective and safety equipment, necessary to test, monitor, enter, work in, and escape from permit spaces. Furthermore, employers are required to provide at least one supervisor outside the permit space for the duration of entry operations. When there are changes in the use or configuration of a non-permit confined space that might increase the hazards to entrants, the employer must re-evaluate that space and, if necessary, reclassify it as a permit-required confined space.

Specific regulatory obligations under the command and control approach will usually ensure a proper management of hazards related to work in confined spaces, but in some cases they will require more than is needed and in others they will not be adequate for the risk. Despite the clarity of what is required, violations are frequent and several companies have received substantial fines. For example, VT Halter Marine, a shipbuilder in Escatawpa, MS, USA faced fines up to USD 1.320.000 for an accident during maintenance in a tank that killed two people and injured others. Seven-figure OSHA fines are becoming more common, especially in cases when OSHA believes the company acted with willful disregard to safety.

Approach focused on oxygen-depletion

There are several countries, such as Japan, South Korea and Taiwan, which focus on the oxygen-deficient nature of confined spaces, and focus their regulatory

requirements on preventing the creation of oxygen deficient atmospheres and the protection of workers from the hazards they pose.

In South Korea and Japan, the law stipulates precise requirements to prevent hazards relating to oxygen deficiency in the workplace. More specifically, the

regulations contain requirements on working environment assessments for oxygen deficient operations, the concentration of the oxygen in the air, the

appointment of a supervisor for oxygen deficiency works, as well as provisions regarding special training, evacuation, ventilation, and protective equipment.

When engaging workers in oxygen-deficiency works, the employer must keep the concentration of the oxygen at safe levels by installing an appropriate

ventilating system, unless this is too difficult or not possible.

Loose or no regulation

Finally, there are those countries where confined spaces are very loosely regulated. Although there are many of these countries, they usually do have general obligations that can be used to cover the use and prosecute the company when things go wrong.

Determine your risk exposure

It is clear that the divergence in global regulatory approaches is not conducive to ensuring regulatory compliance by multinational corporations. In the interests of efficiency, cohesion and best practice, the management of environment, health and safety issues at the corporate level must focus on ensuring that

corporate procedures set high standards. This need is perhaps epitomised by the issue of work in confined spaces. By its very nature it is a universal problem

faced in all countries, and yet the various regulatory regimes deal with the problem in different ways. How can corporate EHS managers develop such all-encompassing procedures for safe work in confined spaces?

Corporate confined space entry procedures appear to be the norm in dealing with the issue internationally. Clearly, establishing a catch-all procedure, ensuring regulatory compliance across the board is the most effective method. Yet, as

with regulators across the world, corporate managers also have to determine themselves how they are to define “confined spaces”. The most sensible approach involves identifying any potential confined spaces and assessing the risk posed, before work is carried out there. A risk analysis will help determine, on a case by case basis, which “confined spaces” within a facility require control and supervision. Any risk assessment would need to consider all the various possible aspects of a “confined space” as discussed above. Figure 4 allows you to test your risk exposure as regards to confined spaces.

If your score is 80 or more, you seem to have things under control. Below 80 you should start to worry. Below 60 you are asking for trouble.

About the authors

Mr Thierry Dumortier and Mr Tjeerd Hendel-Blackford are regulatory experts with Enhesa, a global consulting company specialized in assisting business to ensure compliance with health and safety regulations worldwide. Enhesa systematically researches the health and safety regulations and any related regulatory and policy developments to inform and advise clients on how to respond.

Further info can be found at staging.enhesa.hosted-temp.com

Keep on top of how compliance keeps changing

Stay informed about the world’s top EHS and product regulatory trends, resources and events.